As part of efforts to consistently seek out higher standards of fire safety, it is only natural that the industry will focus its energy on developing sustainable and highly reliable solutions with proven efficiency . Within this context, the use of magnesium hydroxide as a flame retardant material has emerged as a smart, practical and high-performance alternative to processes carried out at elevated temperatures — and in this article we explain why!

The importance of thermal resistance

Those of us that are involved in the thermoplastic and elastomeric compounds industry, know too well flame retardant and suppression characteristics offer an important competitive advantage. These characteristics are also indispensable in ensuring that these components deliver the necessary resistance under the conditions and processes involving elevated temperatures and, in extreme cases, are able to minimize potential situations of risk.

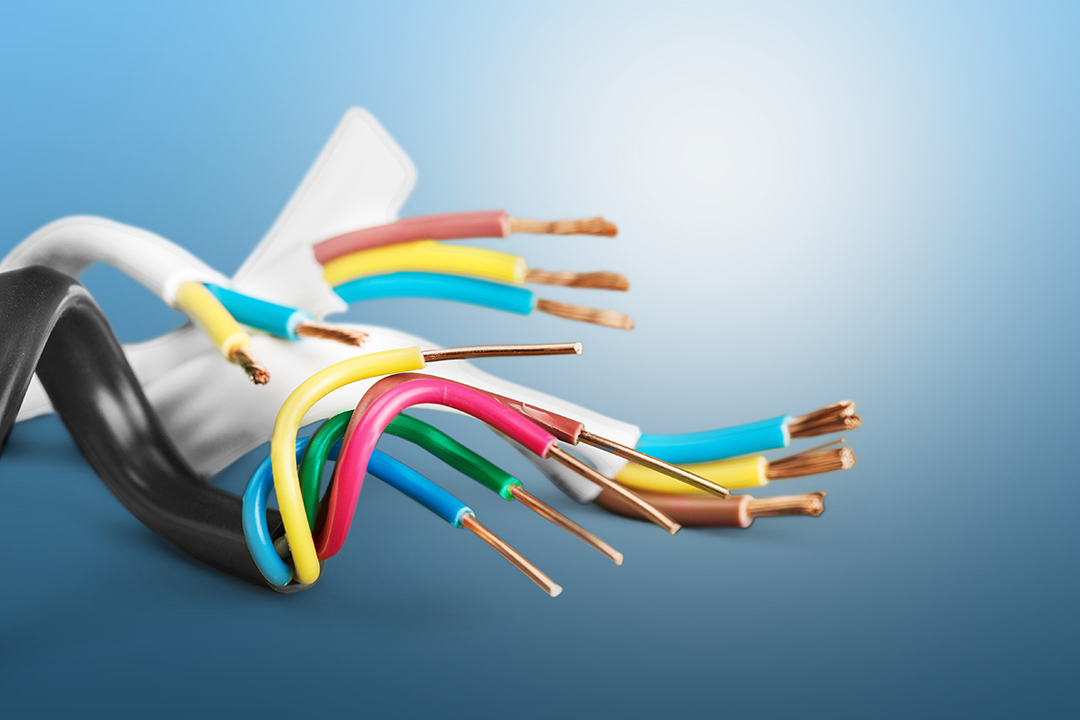

It is a well-established fact that flame retardant materials are capable of decomposing when exposed to high temperatures and promote a decrease in heat and a high insulation matrix, thereby inhibiting the propagation of flames. It is precisely these characteristics that makes these substances ideal for applications involving thermoplastic and elastomeric compounds, which are often used to manufacture materials that are more prone to short circuits and fires, such as electrical wires and cables.

However, from among the possibilities offered in the industry in order to meet these demands, it is equally important to understand how to choose alternatives that, in addition to offering an excellent cost-benefit, also guarantee an increased service life and resistance without sacrificing sustainability or quality throughout the production process. It is within this context that the application of magnesium hydroxide as a flame retardant material emerges.

This is due to the fact that, as a result of magnesium’s specific characteristics, this element is able to offer a high level of thermal resistance. It is therefore ideal for application in products that must be subject to processes carried out at high temperatures without degradation or release of the retardant material. For example, materials that use magnesium hydroxide as a flame retardant element are capable of maintaining stability at temperatures of up to 340 ° C.

These results are significant, especially when we consider that aluminum hydroxide — the most common alternative to magnesium hydroxide available on the market — loses its stability at 200 ° C, which limits its application in polymer matrices that require high processing temperatures. Magnesium hydroxide therefore offers flame retardant properties that are 17% more efficient that those of aluminum hydroxide.

Magnesium hydroxide’s action as a flame retardant material

In practice, magnesium hydroxide provides the following principle of action when used as a flame retardant material when exposed to temperatures above 340 °C, magnesium hydroxide decomposes endothermically, which means that is absorbs heat while generating water vapor and magnesium oxide. Water vapor from the magnesium molecules initially act directly to reduce the heat produced by the respective medium and suppress the smoke generated. Magnesium oxide coats the surface of the material, forming a protective layer that prevents the oxygen in the air from coming into contact with the combustible material, thereby preventing flames from spreading.

Additionally, due to its basic nature, magnesium hydroxide also helps to neutralize toxic gases that may come to be released during combustion of polymers such as monoxide and carbon dioxide, sulfur dioxide or nitric oxide gases, which are extremely harmful when emitted in larger quantities. Magnesium hydroxide is able to provide all of these advantages even in its most basic form.

We also cannot forget to mention that, depending on the specific application and purpose, magnesium hydroxide may also be coated in fatty acids such as stearin in order to act more intensely in the dispersion of polymer matrices, thereby increasing the amount of the materials that are used in the polymer’s composition and reinforcing the structure of materials.

Hydromag FR and Hydromag FRC: increased safety and resistance in applications

As previously mentioned, the use of magnesium hydroxide as a flame retardant material in any scenario offers a series of practical benefits that, from a technical perspective, help to guarantee increased safety and resistance across a wide range of applications. For these reasons, Bel Mag makes the Hidromag FR line, which was exclusively formulated and specifically developed for demanding projects, available to manufacturing plants.

Due to its small particle size, Hidromag FR products can be easily incorporated into polymer matrices, improving yields without compromising the efficiency of its fire retardant properties. In addition, our products are naturally sourced and therefore 100% halogen-free, which prevents acid gases from being formed during polymer combustion and, as a result, reduces erosion rates in equipment and components.

Magnesium hydroxide can be found in our catalog in both the Hydromag FR versions, with all the benefits listed above, and Hydromag FRC, which combines these characteristics with a powerful stearin coating that increases the rate of dispersion.

And of course, by choosing a product on the Hidromag FR line, you are relying on solutions of a marine origin that provide production processes involving thermoplastic and elastomeric compounds with increased safety, a significant cost reduction and a high level of performance. In short, the use of magnesium hydroxide offers a wide range of advantages:

- Flame retardant material up to 17% more efficient than aluminum hydroxide;

- Smoke suppressant that promotes the formation of a protective barrier;

- Free of halogens such as chlorides, which cause corrosion;

- Thermal stability at temperatures of up to 340 oC;

- Capacity to neutralize gases formed during combustion of polymers, such as C02, NOx, SO2 etc.

Would you like to learn more about Hidromag FR products and the advantages they offer? Get in touch with our team today!

Leave your comment